News

Protect Your Facility with R&B's Bumper Trucks | Video

The loudest complaint we have continually heard from facility managers over the years is that all of the transport products used in facilities are not made to protect the facility. When trucks and carts hit walls, doors and equipment, they can cause tens of thousands of dollars in damage annually. These are real and ongoing costs that facilities incur year after year. Now there is a solution!

R&B’s market research concluded that facilities in hospitality, healthcare, education and other industries are spending anywhere from a few thousand dollars to hundreds of thousands of dollars annually repairing damage from transport products. The truth is, most transport products are built to last but not built to protect the facilities. R&B has worked diligently to develop products that are unique and will meet the needs of their customers and we have heard the complaints loud and clear about damage. After significant research and testing, R&B introduced the first Vinyl Basket Truck with a Fully Sewn Non-Marking Top Rim Air Cushion Bumper. A truck built to protect your facility and save you money! This product has had rave reviews from the onset and has made a dramatic impact immediately across all markets.

Now R&B has introduced an option to provide this same great protection on our Standard Poly Truck Line with a mounted version of this top rim non-marking bumper. Now you have a choice of dual facility protection – only from R&B Wire Products and our network of international distributors.

Caster FAQ's

Caster FAQ's

What's the benefit of a 'diamond caster pattern'?

A diamond caster pattern is best for moving heavy loads over uneven surfaces where the rocking effect of the diamond pattern (2 larger casters in the middle and 2 smaller casters on each end) allow you to roll the cart or truck with less strain to move a heavy load over a threshold or uneven surface(s).

What's the benefit of 'two rigid/two swivel casters'?

With larger loads it is much easier to steer with two rigid or fixed casters on one end and two swivel on the other. This allows for the attendant to maneuver the cart or truck with more control and helps facilities prevent from carts hitting walls and doors.

What's the benefit of an 'all swivel caster pattern'?

Four corner all swivel casters are great for smaller loads and where you need to navigate in and out of elevators or in tight spaces, allowing you to roll easily in any direction. For example, if you want to roll a cart directly in front of a washer or dryer in a tight space, having four corner casters simplifies this process. At times, heavy loads will make it harder to steer straight with four corner swivel casters, which can cause a truck to wander or veer. Caution should always be exercised while transporting materials.

Why larger casters?

Why do you need larger casters? Normally they are rated for higher weight capacities. A larger caster will have a larger wheel width, allowing the weight to be more evenly distributed over the width of the wheel, which makes it easier to roll. Semi-pneumatic casters and pneumatic casters will also be quieter when rolling on certain surfaces.

What is a "quiet caster"?

A "quiet caster" normally refers to a semi-pneumatic or full pneumatic caster. These are used in instances where there is a need for less noise ("wheel chatter"). These are usually larger wheel size casters of 6", 8", 10" or greater and have wider wheel footprints with softer material that should always be non-marking. The semi-pneumatic has an air or foam internal channel allowing for cushioning. The full pneumatic is an air filled tire just like a car tire.

Why choose one over the other? Both are expensive but the full pneumatic is usually more costly. Secondly, a full pneumatic can get a flat tire while a semi-pneumatic cannot. Both are quiet and can solve many noise related issues.

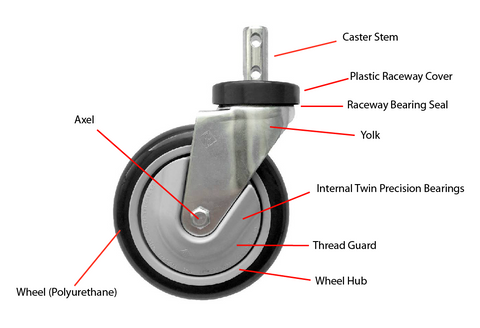

What are the components of a caster?

There are several components to casters – themetal yoke, the top raceway, the wheel and the internalwheel bearings. What are all these? The metal yoke is the housing that the wheel is mounted to, which allows the caster to roll. It is very important to have yokes that areheat treated orcase hardened to make the metal harder and stronger. A yoke that is not heat treated will easily score with a screw driver or hard object, which means the metal is soft and can wear out more easily than if case hardened or heat treated.

Swivel casters have a top raceway where the bearing system allows the caster to rotate 360 degrees - increasing maneuverability. If the yoke is not heat treated these bearings can wear down the inside of the raceway and allow the bearings to become sloppy, causing the raceway to fail.

The material the wheels are made of varies widely and is very important - and softness or hardness matters! Many quality, non-marking wheels are made from polyurethane or TPR (Thermoplastic Rubber). Many other wheels that are less expensive are made of inferior materials which can mark floors. Make sure to ask what the wheels are made of and if they are non-marking. We are proud to say that all R&B casters are non-marking!

The internal bearing(s) for the wheel itself makes it roll smoothly and straight. Inexpensive casters may not even have a wheel bearing. Open bearing systems are vulnerable to debris, which make them noisier and less efficient. A single or dual sealed bearing system is much more desirable as it enhances their effectiveness and life. A sealed bearing prevents debris from damaging the bearing which keeps the caster rolling smoothly for years. In the end you get what you pay for, so know what you are buying.

R&B In The Media

have made appearances in countless movies, television shows

"I love cart" -- Steve Carrell and Kristen Wiig, of Anchorman 2, stand

Third Generation Rawlins Joins R&B Team

Press Release

For Immediate Release

August 11, 2016

Third Generation Rawlins Joins R&B Wire Products

Santa Ana, California --R&B Wire Products

CEO Rick Rawlins is pleased to announce the third generation Rawlins as the newest member of the team. The addition of Grant Rawlins comes exactly 50 years after his grandfather, Rea Rawlins, purchased the company, and 42 years after his father, Rick, joined.

Grant graduated in April from Pepperdine University with his Bachelor’s degree in Integrated Marketing Communication. He stated that he looks forward to bringing his team-focused mentality to the company which was taught to him by his water polo coaches (6x Olympian Terry Schroeder and current Olympic goalie Merrill Moses) during his collegiate career. Grant stated, “I’m looking forward to contributing to the company’s success while continuing the legacy that my grandfather started 50 years ago.”

Frank Rowe, VP, Sales & Marketing expressed, “This is a great legacy at R&B for Grant to be involved in with such a rich family history and being able to take his education and put it into use immediately. His athletic training is a testament to his drive and focus which is a huge plus for our team.”

Rick Rawlins stated, “I’m excited to see Grant pairing his Pepperdine marketing education with R&B’s global strategy in order to secure the company’s growing position as the industry leader.”

__________________________________________________________________________________________________________

Santa Ana-based R&B Wire Products is a diversified manufacturer of wire, tubular, poly, and vinyl bushel products. In addition, they also offer small and large scale custom manufacturing. R&B Wire’s product line serves the coin-laundry, healthcare, hospitality, laundry, janitorial supply, material handling and car wash sectors. As the industry leader, R&B is the standard in the laundry cart business, and has been since its inception in 1946.

Please also see the Press Release at AmericanCoinOp.com

R&B’s New Antimicrobial Laundry Carts Boost CLA’s Charity

R&B Wire Products recently donated two of their brand new Antimicrobial Wire Laundry Carts to the Coin Laundry Association’s Excellence in Laundry Conference 2016 in Ojai, CA. These carts were part of an auction to benefit the CLA’s LaundryCares Foundation.

R&B Wire Products wanted to give a huge “Thank you!” to Chris Balestracci and Super Wash Laundry of East Haven, Connecticut for purchasing these carts and helping them support the LaundryCares Foundation.

The LaundryCares Foundation was created to help give back to the communities who support coin laundries around the country by providing "Free Laundry Days" and various other outreach programs. Follow @LaundryCares on Twitter for more details and upcoming events.

Monsi, Chris Balestracci, and Jenn from Super Wash Laundry are enjoying their new Antimicrobial Wire Laundry Carts.

Caster Maintenance

Keeping your laundromat clean and tidy shows customers that you are concerned about their positive laundry experience. Your customers use your laundry carts as much as, or more than, your washers and dryers. Customers also expect all of your equipment to be in top-notch shape. This helps bring customers back and creates ongoing revenue!

Just like all other laundromat equipment, laundry carts need to be maintained too. Taking care of your laundry carts shows your customers that you care. Taking the time to clean your carts and wipe them down routinely with a cleaning agent or damp cloth works nicely. This goes for the rack, basket, base and casters. Be sure to wipe the carts down immediately with a dry cloth to remove the moisture and debris – keeping your carts bright and dry. Your customers will notice and appreciate this routine maintenance.

The trickiest part of this maintenance process is taking care of the casters – the only moving parts on a laundry cart. The raceway, which allows the caster to swivel, and the internal precision bearings, which allow the caster to roll, are the two “Achilles Heels” of a caster. This is due to the fact that these two components tend to attract hair, lint and other debris, causing the caster to make noise, not roll smoothly or even lock up. Think about the last time you were at the supermarket and the shopping cart you were pushing had a jammed wheel full of hair, lint and other debris – not a pleasant experience!

Here are two options you have to solve this caster maintenance problem, depending on the casters you have.Non-R&B Casters

- If necessary you can open the raceway to clean the bearings and repack them with grease. Ultimately, an open raceway will yield the same problem again and again. Avoid using a degreaser lubricant (like WD-40) as this will be counter-productive.

- Next, remove the axle bolt and nut from the caster to remove the debris that has wound around the axle nut and bolt.

- Once you have removed the nut and bolt, clean the inside of the caster as much as possible. Clean the nut, bolt and center axle as much as possible with a clean rag. You will likely find that the bearings inside need to be removed and cleaned.

- Replace the nut and bolt until properly tightened. Your customers depend on your carts and expect them to function properly. Depending on how much traffic your laundromat gets, you may have to clean the casters every month. Poorly functioning carts can cost you customers!

R&B's "Clean Wheel System" Casters

R&B Wire’s patented "Clean Wheel System" casters, come standard on all of our laundry carts. These 5" casters are equipped with our proprietary "Clean Wheel System", featuring our plastic raceway cover and Thread Guard, both designed to minimize any debris pick up. If they ever do pick up any debris, it should be easily removed. We are proud to say that these casters are designed to be virtually maintenance free!

R&B Wire Products Ramps Up Antimicrobial Product Line

Santa Ana, CA (July 18, 2016) -- R&B Wire Products announces their complete line of Antimicrobial products, including their Antimicrobial Laundry Carts (100E/ANTI, 200F/ANTI, 201H/ANTI), Antimicrobial Triangular Hamper Stand (669/ANTI), Vinyl Basket Truck W/ Antimicrobial Liner (406SO/ANTI-420SO/ANTI) and Antimicrobial Privacy Screens (PSS-3/AML, PSS-3C/AML). Click here to view the complete line.

These products feature an Antimicrobial additive which is designed to inhibit the growth of bacteria and provide an unprecedented level of cleanliness for employees and guests alike. These products are designed to help facilities meet strict health codes and regulations.

R&B also offers Antimicrobial hamper bags and covers in a variety of colors for maximum protection.

These product lines will ensure facilities an added level of protection to minimize bacteria while enhancing cleanliness – showing customers that they care. Additional information and pricing is available by visiting www.rbwire.com or calling 800-634-0555.

Antimicrobial Laundry Cart Line

A NEW product innovation from the “Leader in Laundry Carts”! R&B Wire Products announces their NEW Antimicrobial Wire Laundry Cart line. This new Antimicrobial powder option creates the FIRST wire laundry carts with an Antimicrobial powder coated base, basket and bumper that inhibits the growth of bacteria – providing a new level of cleanliness by preventing bacteria from sustaining life on the surface of the carts. The entire base, basket and rack has an Antimicrobial additive incorporated into the coating for lasting protection. This coating is put through strict quality testing and is in accordance with ISO22196, the international standard. The proprietary antimicrobial blend present in this coating is not only effective, but also environmentally sustainable.

Additionally, this cart’s antimicrobial bumper adds an additional layer of protection not only against microbes but also against damage to equipment and walls.

R&B also offers Antimicrobial basket liners and complete cover kits in Antimicrobial vinyl for maximum protection. Additional options and carts are being evaluated and will be added to this Antimicrobial line in the near future.

This NEW product line is offered in three size options – 100E/ANTI (2 ½ bushel), 200F/ANTI (4 ½ bushel) and 201H/ANTI (6 bushel) with options for double pole and single pole racks, all with our antimicrobial coating.

This new offering will allow any laundry, healthcare facility or alternative environment to have the added level of protection to minimize bacteria while enhancing cleanliness – showing your customers that you care. Additional information and pricing is available by emailing sales@rbwire.com or calling us at (800)-634-0555.

Deter Laundry Basket Sitters!

Are you tired of customers putting their children in your laundry carts? Sick of teenagers damaging laundry carts with “Evel Knievel” stunts? Not only does this annoy other customers, it also poses a major danger and liability to these wannabe stuntmen and other customers in your laundromat.

R&B Wire Products launched the No-Ride Basket Device (100BSKINSRT) in order to deter potential basket sitters. This device is designed to make it extremely uncomfortable for someone to sit in the laundry cart, while not inhibiting the performance capabilities of the cart itself. The strong 9 gauge wire has a clean look with a white powder coated finish. This device fits all of our 100 series laundry carts and comes with hardware.

If you have issues with basket sitters, this product is a must for your laundromat. Only available from R&B Wire Products – “The Leader in Laundry Carts”.

R&B Wire Products Celebrates July 4th

R&B Wire was created in California in 1946 as our troops were returning home from World War II. R&B Wire began during the postwar economic boom, when American manufacturing was shifting its focus from making war equipment to creating useful products for everyday Americans. It was the perfect storm for launching our first laundry cart as the Self Service Coin Laundry industry was just beginning. By pairing the need for laundry equipment with American manufacturing expertise, we created our first laundry cart.

As a company based in America and run by three generations of proud Americans, we would like to wish everyone a Happy Fourth of July, including our troops and veterans whose service we are thankful for!

R&B Wire Products – Proudly serving our customers, standing behind our troops and supporting our nation since 1946.

70 Years of Manufacturing Excellence

Dear R&B Customers,

Thank you very much,

Rick Rawlins, CEO